8th March 2022

What better way to celebrate International Women's Day than by making the wheels for our new car!

Yes, that's right! After spending lockdown designing the latest edition to the CAUC fleet, we are finally able to begin the build process...starting with the wheels!

To begin with, we split up into three teams; Preparation, Cutting, and Mixing.

Team 1 Preparation:

Under the supervision of Richard, Lily and Neve prepared the jig by applying wax to each surface.

Whilst Richard, Neve and Lily were busy preparing the jig, Alice and Erin where in charge of preparing the wheel rim. This involved wrapping the wheel rim in masking tape and carbon fibre tip.

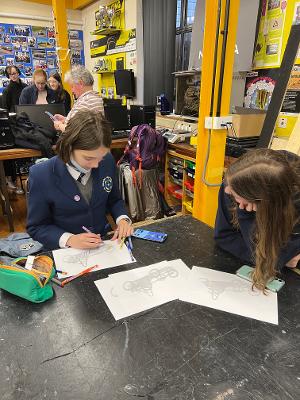

Team 2: Cutting

Emily's team were in charge of cutting. Darcey, Daphne and Liberty were required to cut out four pieces of Carbon Fibre...accurately using a spare wheel as the template!! Once cut to size, the next task was to cut out a star shape in the middle of the material which will be peeled back once laid on the jig.

With the carbon fibre ready, Team Emily moved onto cutting out the peel ply and nappy ready for the build process.

Team 3: Mixing

Last, but by no means least, Team 3 were in charge of mixing the Epoxy resin, hardener and glass bubbles.

...As you can see, Mr Ebsworth kept a watchful eye as Cerys, Phebs and Amelie were let loose on the pouring and measuring!!! At least we've learnt from past mistakes with Basil and remembered to put the hardener in this time!!!

With everything prepped, it was time to get cracking with the wet lay-up!

To begin with, we placed two pieces of carbon fibre onto the jig and the epoxy was used to wet it out.

Then, we placed the wheel rim and foam onto the jig, peeling back the flaps of carbon fibre in the middle (...from the star shape cut into the material by team 2!).

Any gaps were filled with glass bubbles before the aluminium centre was fixed to the jig.

Layers three and four were subsequently applied and, again, were wet out using the Epoxy. This is where it got a little messy - aprons were definitely needed.

...Erin was clearly in her element stating 'the messier, the better'!

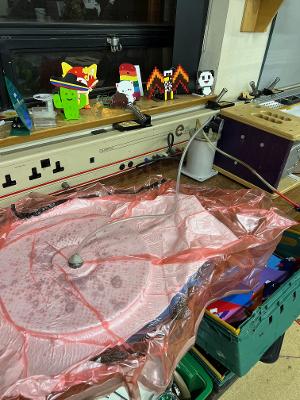

With all layers of carbon fibre and packing pieces sufficiently wet out, it was time to bag it all up. In order to do so, we first had to add a layer of peel ply before a layer of nappy.

Next, it was all hands on deck to gently lift the wheel jig into the bag, being careful not to tear or puncture the bag.

Once safely in the middle of the bag, we had to create a small hole for the vacuum port before using tape to seal the bag. Daphne was in charge of making sure the bag was sufficiently sealed and no air could escape that would prevent a vacuum being created.

All that we had to do now was apply the pump and leave it overnight.

How exciting. First component of CAUC car number 9 (semi) complete!!

As if building our first wheel wasn't chaos enough, the remainder of the team were busy working on a number of other tasks.

Yasmin, with the help of Becksy and Amelie were working together to fit Basil's horn switch back onto the steering wheel. With a narrow cockpit, it required small fingers and lots of patience!!!

Meanwhile, Bethan carried on with the battery discharging project.

Lily and Lara worked together to re-build our kit car, this week focusing on the wheels, whilst Sam and Immy worked on designing the bodywork.

Jess continued to print and re-apply Basil's vinyl stickers. This little project hasn't been without it's issues and Jess, like a true engineer, as worked meticulously to resolve them! Basil will be looking pretty slick when he returns to the race track...even if we do say so ourselves!!

Finally, team captain Cate was busy organising our first event of the 2022 season.

So as you can see, there was a real buzz in the tech suite tonight and the perfect way to end International Women's Day.

I'm not sure how we can top this next week, but we'll certainly try!